Already lost a hot shoe cover or a lens cap? Can happen quite easily. You either buy it quite expensive from the manufacturer or a bit cheaper from a third-party vendor. I bought the other day a 3D printer and ask myself whether I could print the accessories. Here I would like to share my experience, of how I 3D printed camera accessories.

What you need to made photo accessories with a 3D printer

Sliding calliper to measure the original object

Before you can print photo accessory you need the dimensions of the original. A sliding calliper helps you to get those precise enough. I’m using one with digital display. With it, it is easy to get the values which you are using in the 3D software.

Software to generate 3D data

The 3D printer needs 3D data, which you can generate with specialised software. You can find several different types, but I used them for the moment Sharp3D. Professional software, which you cause with some limitations for free. Whether you can accept those or not is up to you. You find detailed information on the website.

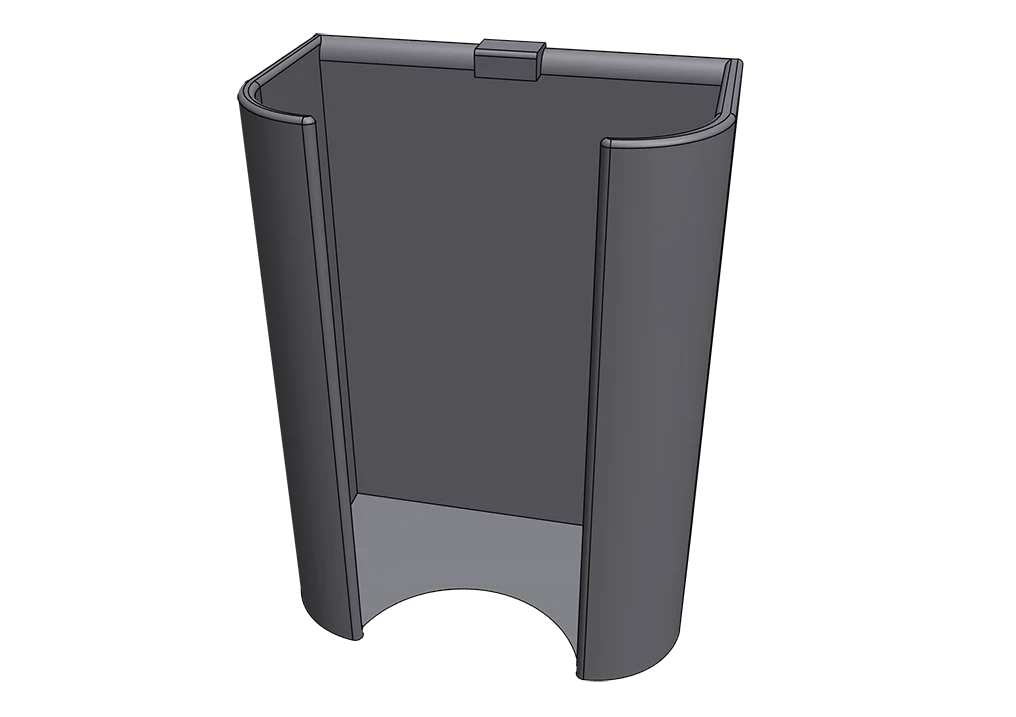

The advantage of Sharp3D is, that you get directly in the app a small explanation video on how to use the chosen tool. This helps a lot to learn the software quickly. My 13 year old son and I managed this quiet easily, so you will do it also. In the image above you see the hot shoe cover for an Olympus / OM Systems camera, which is made by my son.

3D printer

For printing you need a 3D printer. Nowadays no problem. You can get one already below 100€. I bought the Monoprice MP10 printer, which cost me 189€. An investment I was willing to make.

Software to prepare printing data

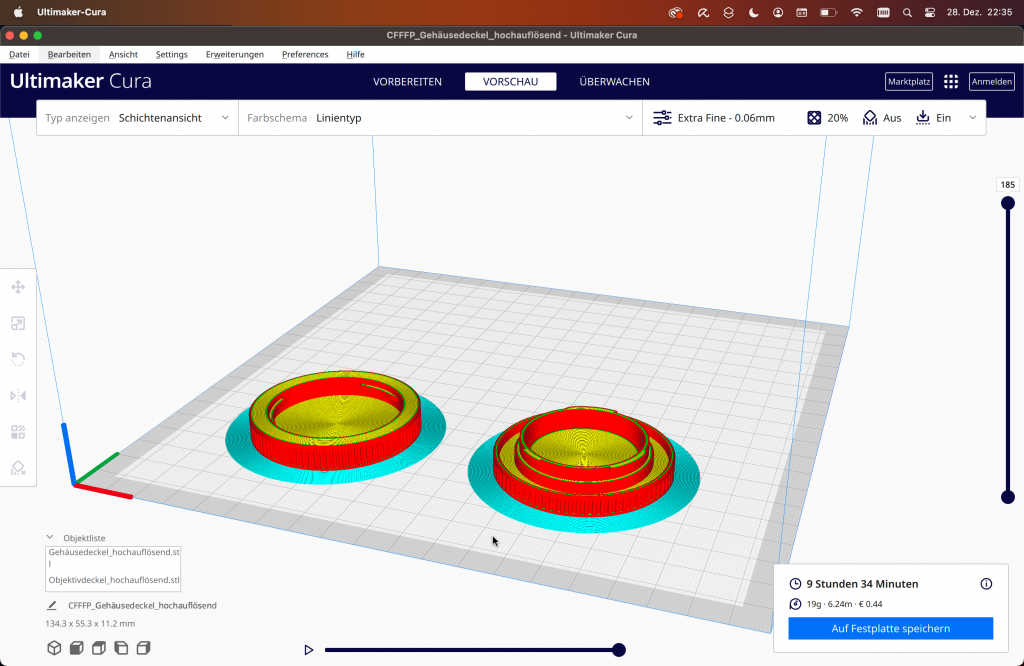

When you have finalised your 3D data, you must prepare them for printing. The object will be divided into layers. Again you can choose between different software, I’m using Ultimaker Cura.

This program and the settings are a bit more complex. The settings depend on many parameters. In particular, the filament and the printer type you are using have a huge influence. Also, the resolution is a factor. You must experiment by yourself, there is no other way. This is fun and you will have very fast a feeling of success.

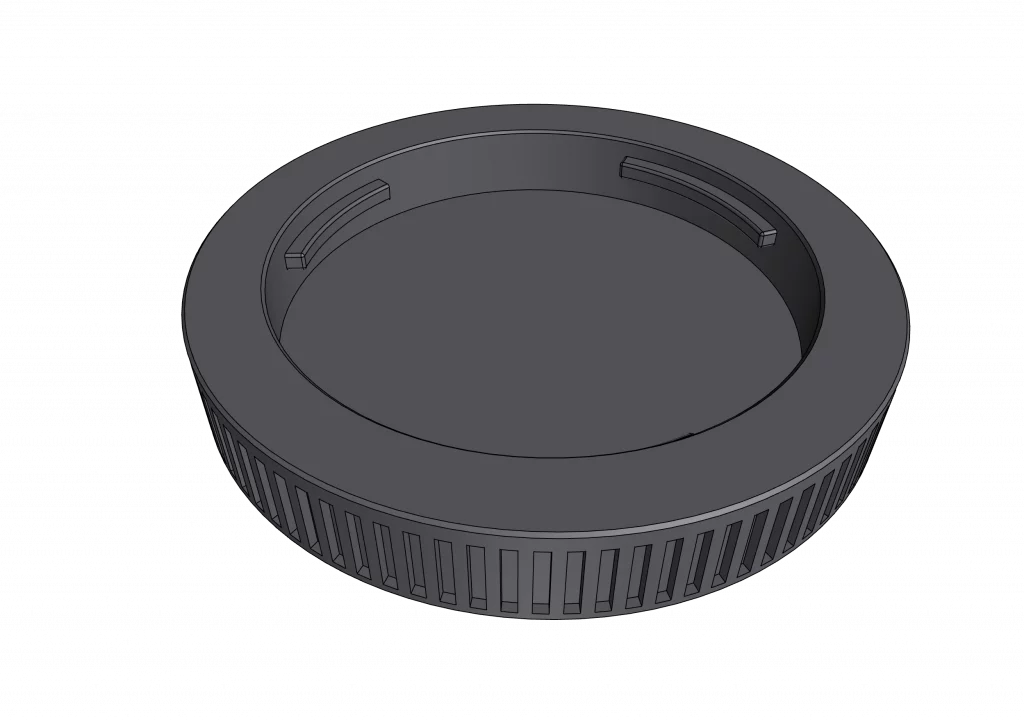

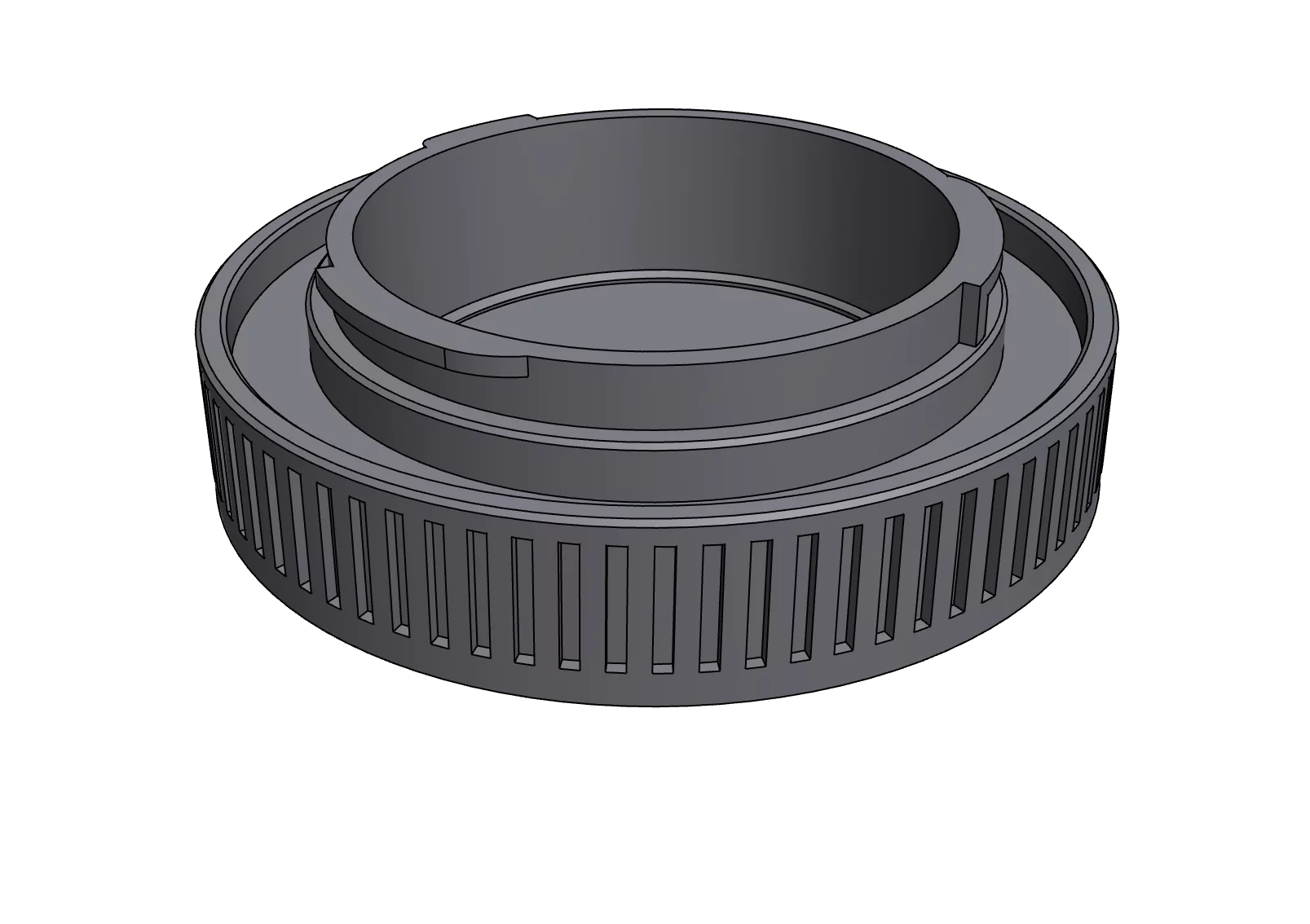

Very important is how you position the objects. As you can see in the image above, the lens cap and body cap lay on their flat sides. A 3D printer is not able to print into the air. Would I lay the object on the other side, I must use supporting layers. It needs not only additional material but is also complicated to remove. Therefore, if possible, the objects should be placed so that there are no cavities downwards.

What accessories can you print with a 3D printer?

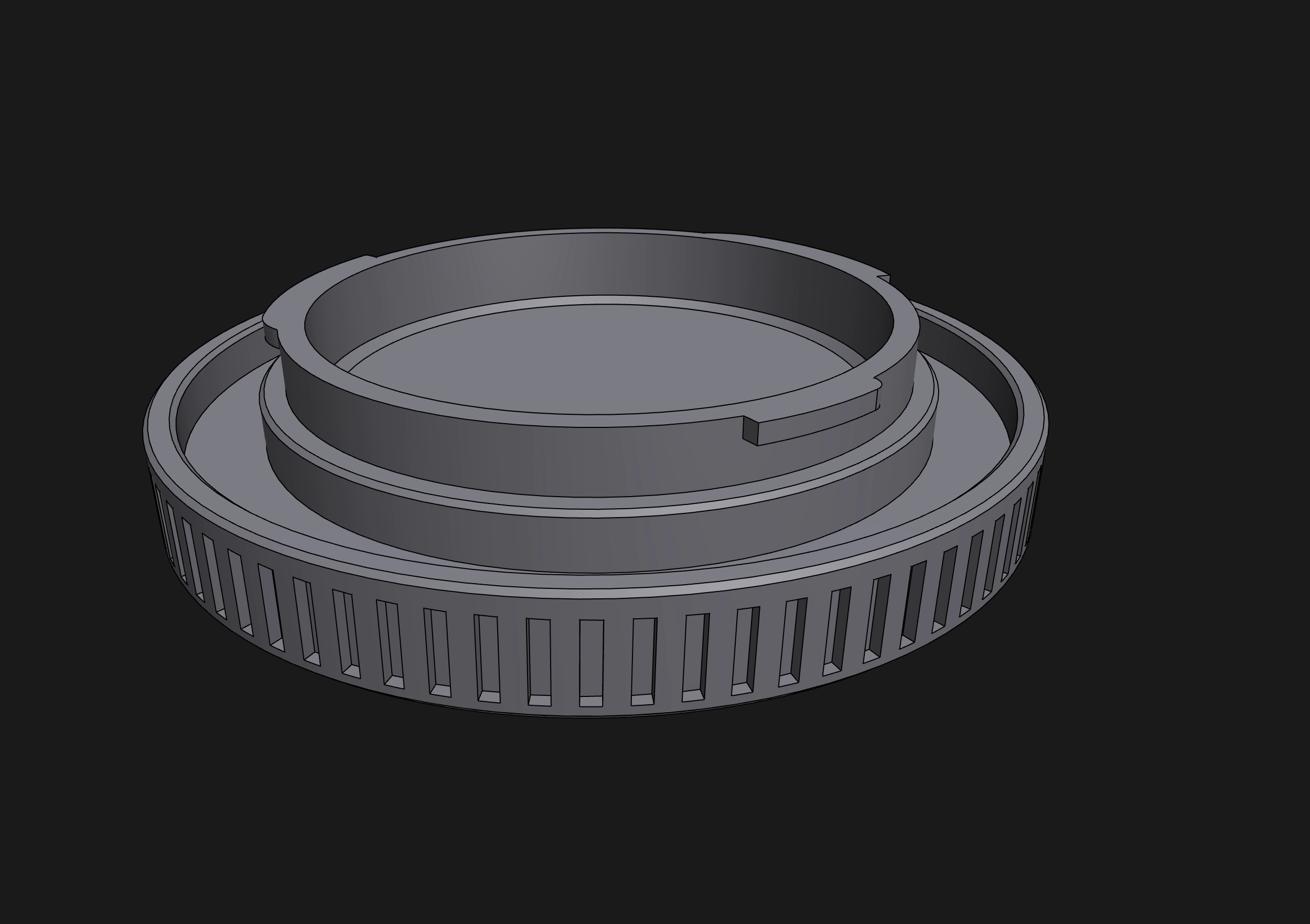

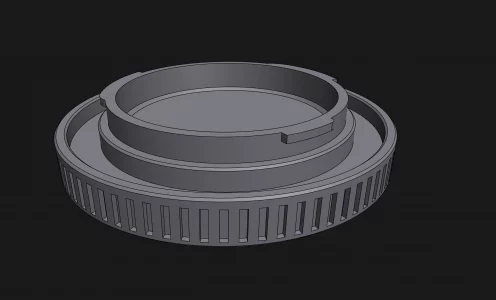

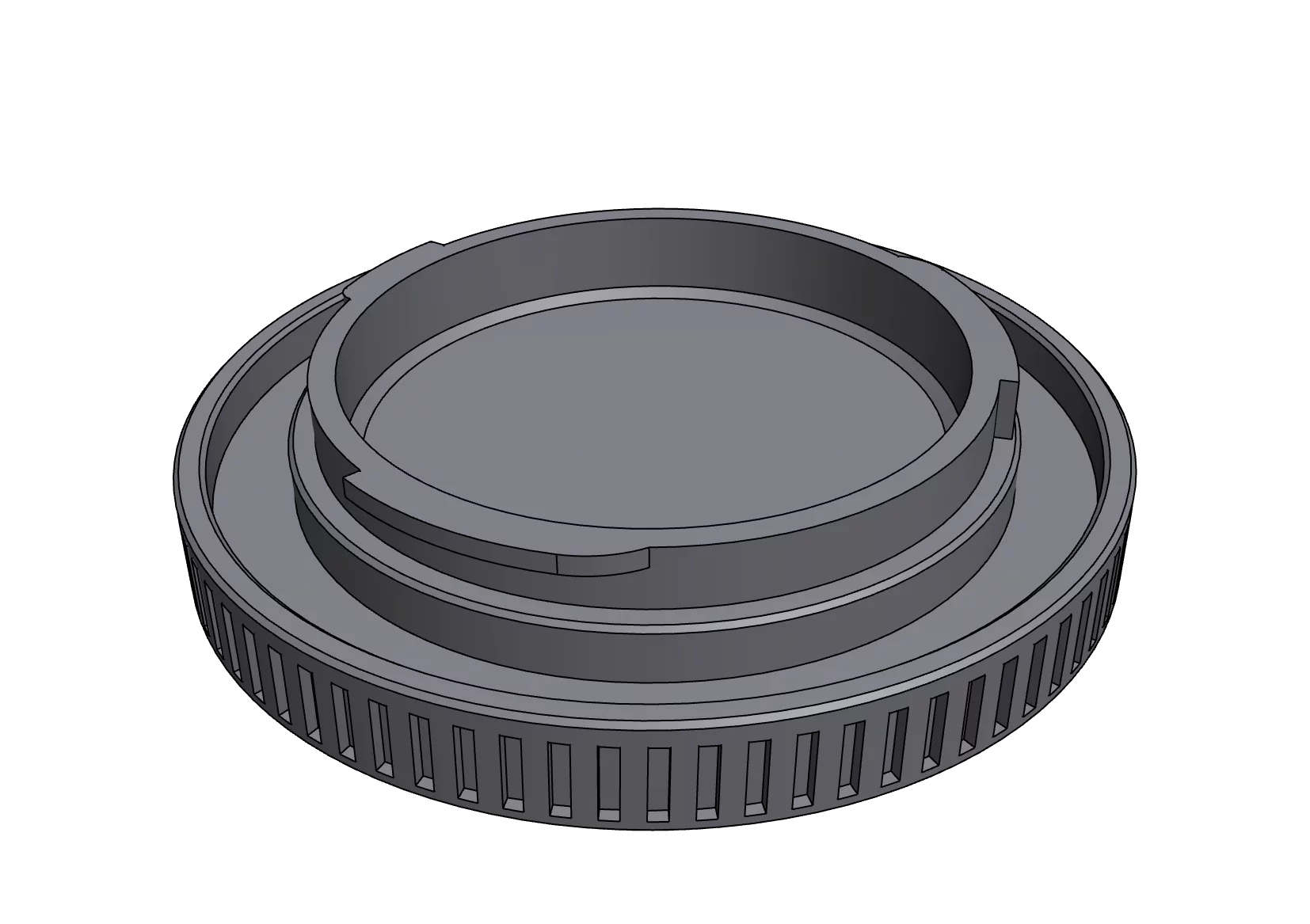

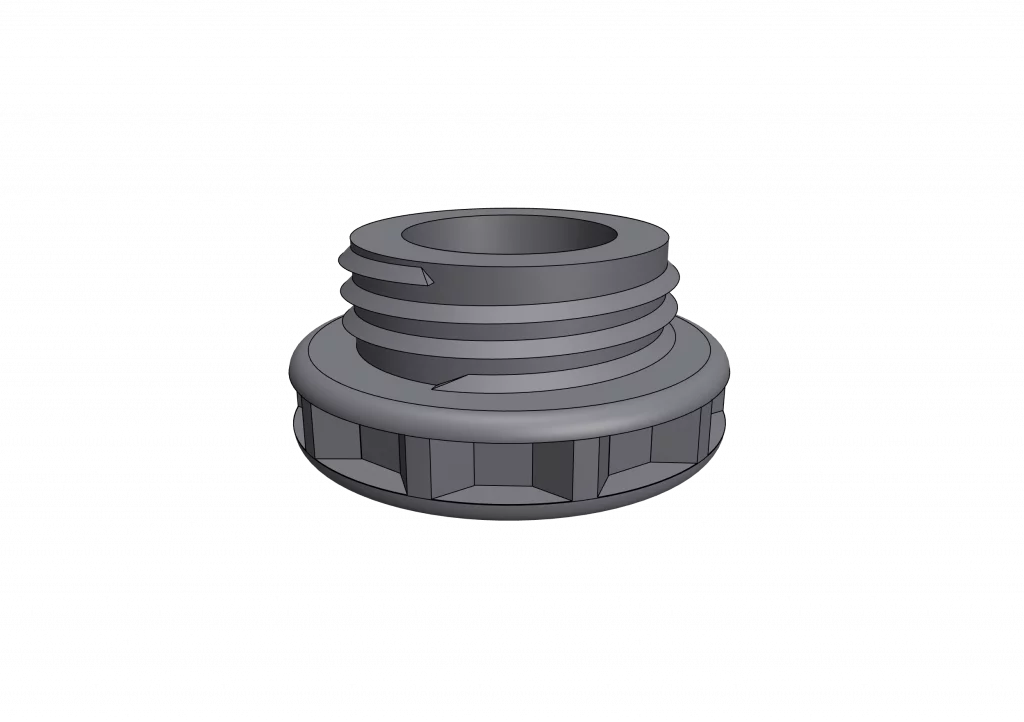

I printed only simple accessories such as a lens cap, body cap and a hot shoe cover so far. However, only a view object cannot be printed with a 3D printer. I already saw a filter holder for the M.Zuiko Digital ED 7-14mm F2.8 PRO which is printed with a 3D printer. In theory, it is even possible to print the cover for the power battery grip, as the flexible filament is also available. Also, wooden accessories or carbon accessories are possible. The appropriate filament is also available for this purpose. As you can see, the possibilities are endless. You just have to let your imagination run wild and think about how best to implement the idea.

My 3D date to print accessories with your 3D printer.

As you can see in the images above I made already some accessories for OM System cameras. In case you own a 3D printer I’m happy when you use them for your own needs.

In case you don’t own a 3d printer, let me know. I can print any part and send it to you. Just write an email, we can discuss the details. When you have your own ideas to realise let me know in the comments. I will have a look and try to make it happen.

Thank you for this excellent article It was very helpful and informative.

Hi Andrew,

So kind of you. Happy that you like it.

Really good to see this post Michael and you seem to have got to grips with 3D Printing technology really well. Can you post some photographs of the models that you have made? It would be interesting to show off the quality you can get when using a relatively inexpensive 3d Printer.

Thanks Alan, yes I have the plan to post also real images as soon as I have time to make them.